Food Safe Silicones

Premium mildew resistant acetoxy and neutral curing silicones. Certified to FDA CFR 21.177.2600(e) and EC1 Plus

SILICONES

Polyurethanes, Hybrids and MS Polymers

Acrylics and Butyls

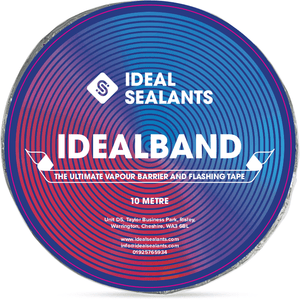

Additional Products and Accessories

-

Quotation on Request

-

Quotation on Request